Aluminum heat sink is also called aluminum radiator or Sunflower aluminum profile. Aluminum heat sink has the advantages of beautiful appearance, light weight, good heat dissipation, and good energy-saving effect.

The surface of the finished aluminum heat sink is anodized for surface treatment to increase the corrosion resistance, wear resistance and appearance of the aluminum.

Aluminum heat sink, copper tube fin heat sink, aluminum heat sink, Copper and aluminum finned tube heat sink, Brass string aluminum sheet, Radiator manufacturers, Electronic heat sinks, Profile radiators, Fin-type heat sink

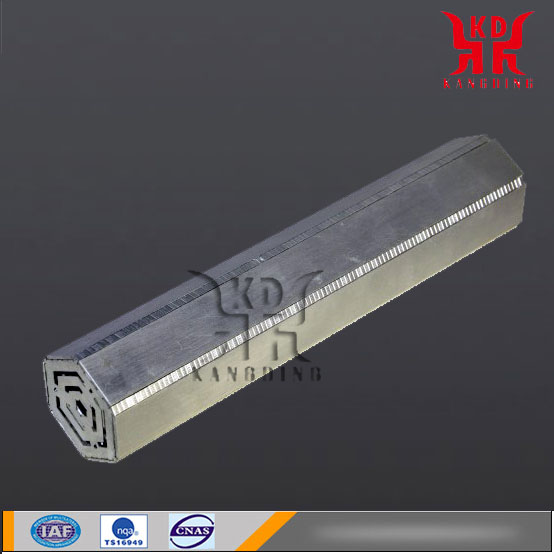

Fin-type heat sinks are the most widely used heat exchange devices in gas and liquid heat exchangers. It is to add fins on the common base pipe, which can achieve the purpose of enhancing heat dissipation. Base pipe can use steel pipe; stainless steel pipe; copper pipe and so on. Fin can also be used with steel strips; stainless steel strips, copper sheets, aluminum sheets, etc.

Working Principle

Heat sinks are devices that dissipate heat from electronic components. Mostly made of aluminum alloy, brass or bronze plate, sheet, multi-chip, etc.

If the CPU in the computer is to use a relatively large heat sink, the TV power supply tube, Line tube, power amplifier tube in the amplifier should use heat sink.

In general, the heat sink must be coated with a layer of thermal grease on the contact surface between the electronic component and the heat sink. The heat emitted from the components is transmitted to the heat sink more efficiently, and is then dissipated into the surrounding air via the heat sink.

Selection

Finned tube heat sinks can be divided into two types: fin type, string type, welding type, and rolling type. Commonly used materials for steel; stainless steel; copper; aluminum and so on.

Copper heat sink, copper-aluminum combined heat sink, heat pipe heat sink, iron heat sink, graphite heat sink, aluminum heat sink, aluminum heat sink

Fin copper tube heat sink

A finned copper tube radiator includes a main body portion and two connecting portions. Two fixing holes are respectively provided at two ends of the main body portion, a perforation is partially formed in the main body portion, and an engaging portion is protruded toward a side of the heat dissipating fin at the perforating portion, so that the heat dissipating fins are perforated and connected. The part is joined with a copper pipe. The connecting portion is formed by extending vertically outward from both ends of the main body portion, and includes a vertical portion and a bearing portion. The vertical portion includes a first receiving block and two second receiving blocks. A first receiving portion is formed on each side of the first receiving block, and a second receiving portion is formed between the second receiving blocks. The carrying portion is formed to extend vertically from the second receiving portion of the vertical portion and is parallel to the main portion, and two fixing protrusions are convexly arranged on the fixing hole corresponding to the main portion. .

Material

Steel heat sink: Mainly: steel double column, steel three column, steel four column, steel five column, steel six column and other heat sinks

Aluminum heat sink: Die-cast aluminum heat sink, steel-aluminum composite heat sink, all aluminum heat sink

Copper-aluminum composite heat sink, copper heat sink

Superconducting heat sink

Cast iron heat sink

Currently used heat sink materials are copper and aluminum alloys, both of which have their advantages and disadvantages.

The thermal conductivity of copper is good, but the price is more expensive, the processing is more difficult, the weight is too large (many copper radiators exceed the CPU's weight limit), the heat capacity is small, and it is easy to oxidize.

The pure aluminum is too soft to be used directly, and all aluminum alloys used are able to provide sufficient hardness. The advantages of aluminum alloys are low price and light weight, but the thermal conductivity is much lower than that of copper.

Some heatsinks take their own advantage, and a copper plate is embedded on the base of the aluminum alloy heatsink.

Features

Aluminum heat sinks, although slow in heat absorption, but emit heat quickly, the heat dissipation effect is proportional to its structure and workmanship. The more heat sinks, the better the bottom polish, the better the heat dissipation effect, but it is also constrained by its manufacturing process. Generally, the minimum spacing of the heat sink grooves in the aluminum extrusion manufacturing process can only be 1.1 mm.

The principle of heat dissipation is also the simplest: use the heat sink on the heat sink to increase its contact area with the air, and then use the fan to accelerate the air flow and take away the heat on the heat sink. The heat capacity of the aluminum heat sink is low and the heat release is fast. The device works better. It is much cheaper than copper heat sinks.

Copper heat sinks, with high heat, use copper heat sinks to dissipate heat. Because aluminum does not achieve the former effect, with heat dissipation this is the leading advantage of copper over aluminum. But its high heat capacity means that the heat sink absorbs heat quickly, but it emits heat slowly. There is a lot of heat in the physical deposition of copper. Need to cooperate with high-power and high-speed fans to achieve the desired results. The heat sinks for both types of materials have their own strengths and can be purchased according to their own needs.

Production Process

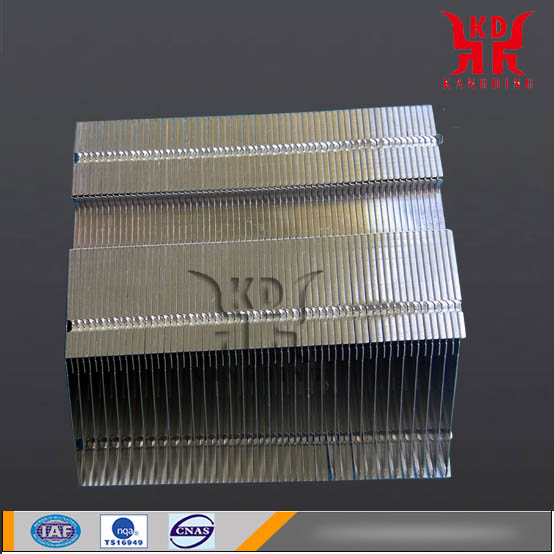

1.Aluminum extruded heat sink

Aluminum materials have been used in the radiator market since they were soft and easy to process. Aluminum extrusion technology is simply to heat aluminum ingots at high temperatures. The aluminum liquid flows through the grooved extrusion die under high pressure The heatsink embryos were made, and then the heatsink embryos were cut, grooved, etc., and then made into our common heat sink.

Aluminum extruded heat sinks have low cost and technical thresholds are not high, but due to their own material limitations, the ratio of the thickness and length of heat sink fins must not exceed 1:18. Therefore, it is difficult to increase the heat dissipation area in a limited space, so the heat dissipation effect of aluminum extruded heat sinks is relatively poor, and it is difficult to be qualified for today's increasingly high-frequency CPUs.

2. Plug copper heat sink

At present, the main material used in the mainstream of the heat sink is no more than aluminum and copper, and the plug copper process is precisely the combination of the advantages of aluminum and copper came into being. The plug copper process is accomplished by the principle of thermal expansion and contraction. After the aluminum extruded heat sink is heated, the copper core is inserted into it, and finally the entire cooling is performed. Because no third-party media is used, the plug-copper technology can significantly reduce the thermal resistance between the contact surfaces, not only ensuring the tightness of copper-aluminum bonding, but also making full use of the characteristics of fast heat dissipation of aluminum and fast heat absorption of copper. This plug-in copper process has moderate cost-effective heat dissipation and is the mainstream type of heat sink on the market.

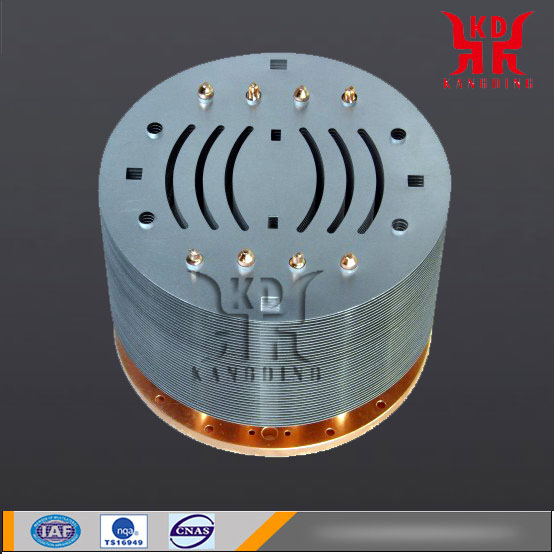

3. Compression method

That is, stacking a large number of copper or aluminum sheets. Then press on both sides and polish the cross-section. This section is in contact with the CPU core, and the other side is spread out as a fin for the heat sink. The heat sink produced by the press-hardening method is characterized by a large number of fins that can be made. And without a very high process, every fin can be kept in good contact with (or close to) the CPU core. The fins are also in close contact with each other by means of pressure fixation, and the heat conduction loss between them is also significantly reduced. It is precisely because the heat sink produced by the compression method has a large number of fins. The heat dissipation effect of such a heat sink is often good, and the weight is much lighter than the conventional heat sink.

4. The cutting heatsink

Compared to aluminum extruded heat sinks, the cutting process solves the limitation of the ratio of the thickness of the fins of the heat sink.

The cutting process is the use of special tools to cut the entire piece of material out of a layer of fins, The heat sink fins can be as thin as 0.5 mm, and the fins and the base of the heat sink are integrated so that no interface impedance problem occurs.

However, this kind of cutting process has many wastes in the process of production, and the impact of low volume yield leads to high cost, so the cutting process is mainly biased towards copper heat sinks.

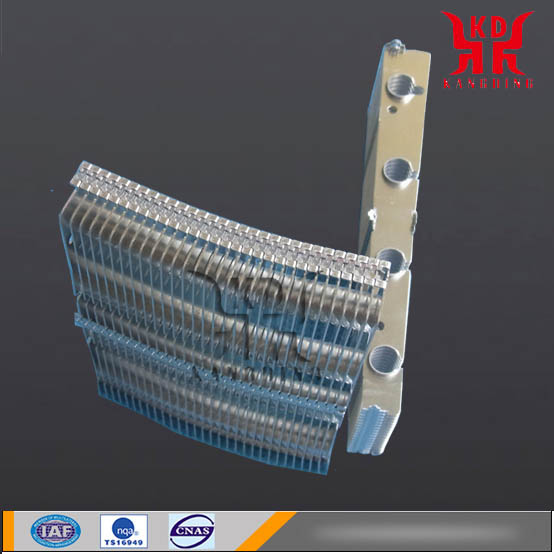

5. Flexible heat sink

The flexible heat sink is a thin plate made of copper or aluminum, which is formed into a one-piece fin by a molding machine. Then, the upper and lower substrates are fixed by a piercing die, and then a high-frequency metal fusion splicer is used to integrate the processed base.

Because the process is continuous bonding, it is suitable for high heat-to-length ratio heat sinks, and because the fins are integrally formed, it is conducive to the continuity of heat conduction. The thickness of the fins is only 0.1mm, which can greatly reduce the material requirements and allow the weight of the heat sink. The maximum heat transfer area is obtained within.